Footwear Mold Making Factory Tour

Footwear Mold Making Factory Tour

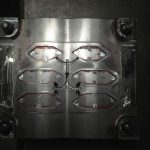

Almost every modern shoe design project will require some sort of molded component. From hidden heel counters, to outsoles, to fancy chrome plated logos you will need make some molds. While some shoe factories will have limited molding equipment, very few will have the capability to make the molds. To make molds for your footwear projects you will need the help of a footwear mold making specialist.

Almost every modern shoe design project will require some sort of molded component. From hidden heel counters, to outsoles, to fancy chrome plated logos you will need make some molds. While some shoe factories will have limited molding equipment, very few will have the capability to make the molds. To make molds for your footwear projects you will need the help of a footwear mold making specialist.

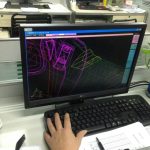

Located in the town of Humen in the heart of the South China shoe making trade, Dongguan Shi Desheng Mold Co. LTD is a typical footwear mold making factory. This factory is well suited to make the plastic injection and compression tooling you may need for your new shoe designs. When you visit a footwear tooling factory you are looking to see a team of CAD designers. They should be busy at work designing the molds. Often the factory technicians will suggest modifications to make your parts stronger or easier to mass produce.

You will also be looking to see CNC machines, EDM machines and milling machines.

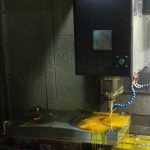

The CNC or Computer Numerical Controlled milling machine is the work horse in the footwear tooling business. You should see CNC machines busy cutting steel molds or copper electrodes. At Dongguan Shi Desheng Mold Company you will see 10 CNC machines cutting. Why 10 machines? When a shoe factory orders molds they will often need the size run opened quickly.

The CNC or Computer Numerical Controlled milling machine is the work horse in the footwear tooling business. You should see CNC machines busy cutting steel molds or copper electrodes. At Dongguan Shi Desheng Mold Company you will see 10 CNC machines cutting. Why 10 machines? When a shoe factory orders molds they will often need the size run opened quickly.

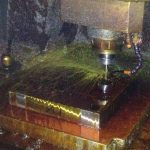

Why are the machines used to cut copper electrodes? Tooling steel is very hard and it can be very time consuming to cut fine details. Also, some details are difficult to cut in the negative required for molding. To make these fine details, a soft copper electrode is cut then used to EDM (Electrical Discharge Machining). The copper electrode is charged with high voltage then slowly lowered onto the steel. An electrical spark will arc from the copper to the steel, burning away a tiny piece of metal. As the electrode moves, the spark will jump to the next highest spot burning away more metal.

To learn more about the Dongguan Shi Desheng’s mold making capabilities you can contact William Wang the Business manager here on Linkedin

Dongguan Shi Desheng Mold Company