Shoe Dissection: See Inside Nike Kobe XI Elite Low

Shoe Dissection: See Inside Nike Kobe XI Elite Low

Today we have a pair of the Nike™ Kobe XI Elite Lows in the Sneaker factory teardown lab. The color is Hyper Grape, Black with a clear gel sole. Sorry to all you Nike and Kobe Fans but we are cutting this shoe apart right now! If you like the youtube channel The Sneaker Chop you will like this.

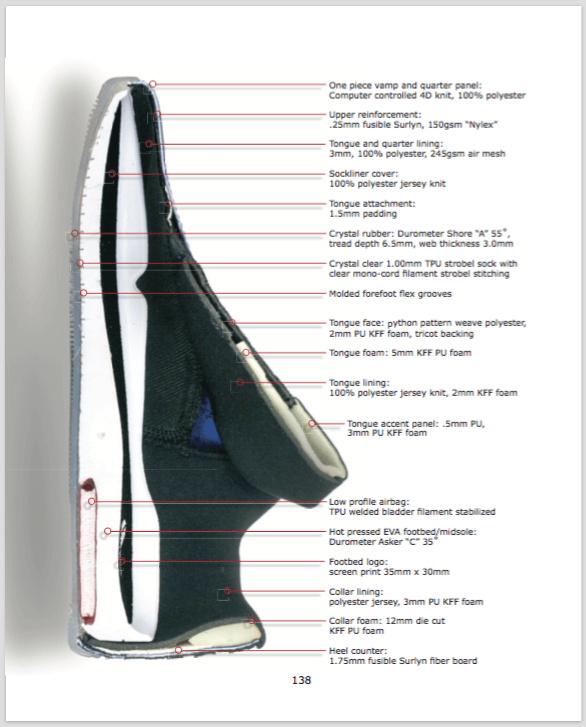

The Kobe XI Elite Low is made by force lasting or stobel lasting. This is the most common construction technique for Air Jordan and Nike basketball shoes. One unique thing about the Kobe XI Elite bottom unit is the clear rubber sole and clear stobel sock. These allow you to see through the bottom and into the shoe. The assembly process for the Kobe XI is conventional except the shoe cement must be clear and have a UV stabilizer to prevent the sole from yellowing. The glue is carefully applied to maximize the see-through effect.

The rubber sole part is made by conventional rubber compression, but the tooling has some special features. The inside of the Kobe IX bottom tooling has a smooth polished finish instead of rough texture designed for maximum bonding. During disassembly we found this did cost Nike some bonding strength, the Strobel was easy to pull off – the bond was not to the standard 4KG per square cm.

The Strobel sock material is a blue-tinted clear nylon plastic sheet. This is a unique Strobel material, most shoes have stitch bonded polyester fabric. The Strobel stitching thread is clear nylon mono cord thread. Mono cord thread is much like fishing line.

The Kobe XI Elite Low also features a drop in combination midsole/footbed. Rather than trapping the midsole between the Strobel sock and the rubber outsole, the midsole is molded with footbed contours on top. The stated benefit is that this allows the foot to be closer to the floor. The downside is the midsole and footbed are now a single density of the foam. In this case, the standing surface has a higher density than a conventionally made basketball shoe. The cost is a reduced “try on” comfort in stores.

The Nike Kobe XI Elite upper is 4K computer knit fabric. The fabric is reinforced with a welded TPU eyestay and non-woven internal eyestay. The tongue lining, internal gussets, and the toe lining are constructed with 3mm air mesh.

If you want to see more check out the book Shoe Material Design Guide

Do you want to be a professional shoe designer? You must learn how to select and specify shoe materials correctly. Our newest book, the Shoe Material Design Guide, details all the shoe materials you will need to make modern athletic, classic casual, and high fashion footwear.

Do you want to be a professional shoe designer? You must learn how to select and specify shoe materials correctly. Our newest book, the Shoe Material Design Guide, details all the shoe materials you will need to make modern athletic, classic casual, and high fashion footwear.

Each chapter covers a specific shoe material type. You will learn how each material is made, the options available, and how to specify the material correctly. We have chapters on shoe leather, textiles, synthetics, shoelaces, glue, reinforcements, hardware, logos, midsoles, outsoles, and more!

We have included annotated cross sections of over 30 different shoe types. You can see exactly how each material is used inside real production shoes. See inside basketball shoes, running shoes, track spikes, hiking boots, work boots, high heels, cowboy boots, and many more!

Do you want to see sneaker chops?

You will also find information on topics such as material testing, sustainable production, exotic materials, and more. Written as a companion to our best selling How Shoes Are Made, the Shoe Material Design Guide digs deeper into the world of footwear materials and design. Softcover, 330 color photos, 28 chapters, 195 pages.