Description

Don't have a clue where to start? start here!

What if you could download the same shoemaking books used to train the staff of the world’s top shoe brands. TODAY.

Would you be interested to know these same books have been translated and are used by Spanish, Chinese, and Vietnamese speaking shoemakers?

What if you could learn about shoe design and the shoe business from an actual working footwear professional?

Do you want to see how the big brands make shoes? Now you can!

More than just a tour through a sneaker factory, How Shoes are Made will show you how modern shoes come to life!

From drawing shoe designs to sample development and footwear manufacturing you will see how it’s done.

Written by veteran shoemaking pros, How Shoes are Made will give you a look inside the REAL world of shoe design, development, and mass production.

26 chapters explaining shoe design, shoe pattern making, sample development, footwear materials, stitching, outsole and tooling design, EVA forming, final assembly, shoe lasts, shoe factory prices, quality control, shoemaking equipment, starting your own shoe brand, and much more!

Jump-Start your career in the shoe Business

THE SHOE DESIGN PROCESS

Start with a footwear design brief

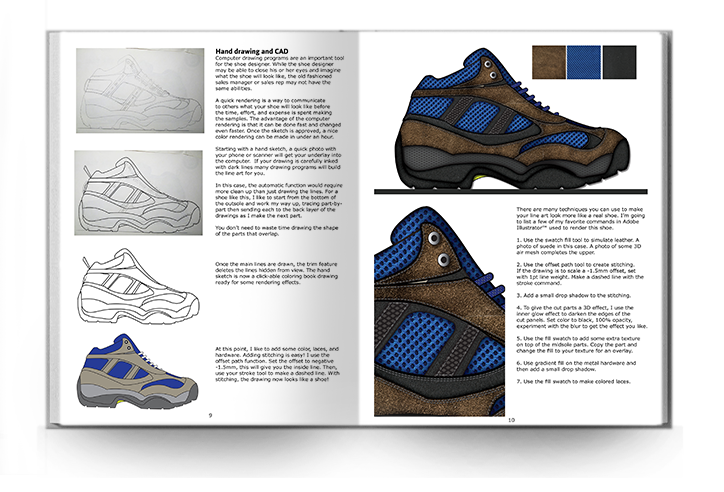

Turn your sketch into a rendering

Make a shoe design pattern

Find the right shoe last

FOOTWEAR DEVELOPMENT

Step by step Transform your design

Outsole tooling mold design

Footwear pre-production process

Shoe material preparations

FOOTWEAR PRODUCTION

Learn how are factory makes shoes

Upper stitching operations

Outsole rubber pressing

EVA midsole forming

The shoe assembly line

MAKE FOOTWEAR SPECIFICATIONS

Learn to create your specifications

What does a factory need to make your design

How to read an outsole blueprint

SHOE MATERIAL SELECTION

Create Logo designs for shoes

Pick the best leather for shoes

Design textiles for shoes

How to use synthetics for shoes

Foam for shoes

THE SHOE BUSINESS

The shoe designers tools you need

Find your job in the shoe trade

What is footwear quality control

Life working at a shoe factory

26 Chapters packed with shoemaking information

1 :THE SHOE DESIGN PROCESS

The shoe design process

Two types of design briefs

Get started drawing shoes

2 : FOOTWEAR SPECIFICATION DRAWINGS

How to make a factory ready specification drawing

What to include in a specification

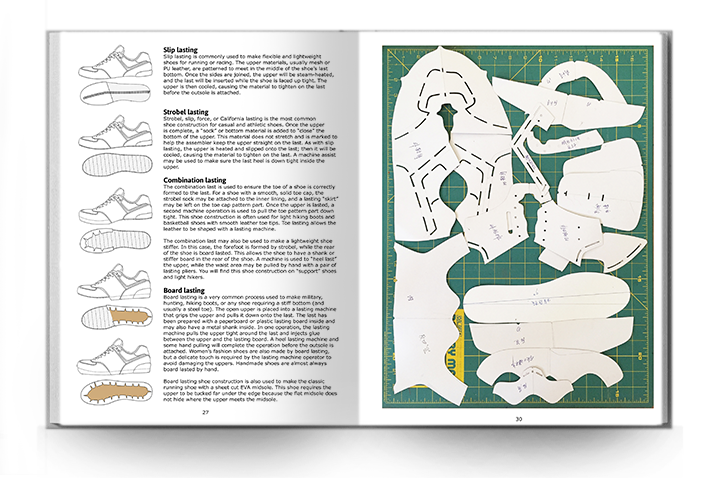

3 : MAKING FOOTWEAR PATTERNS

Shoe designer vs. pattern maker

The pattern maker’s challenge

4 : SHOE SPECIFICATION DOCUMENTS

Parts of a shoe spec

How to detail a spec sheet

5 : OUTSOLE TOOLING DESIGN

Footwear outsole types

Outsole blue prints

Footwear tooling development

6 : FOOTWEAR DEVELOPMENT PROCESS

Footwear sample making

Development sample phases

7 : FOOTWEAR PRE-PRODUCTION

Production size grade

Production cutting equipment

8 : SHOE MATERIAL PREPARATION

Material cutting

Logo printing and preparations

9 : UPPER STITCHING OPERATION

The stitching room

Stitching order of operations

10 : OUTSOLE RUBBER PRESSING

Mixing rubber materials

Rubber molds and pressing

11 : EVA MIDSOLE FORMING

What is EVA made of?

EVA pressing operations

12 : THE SHOE ASSEMBLY LINE

Cold cement shoe construction

Vulcanized shoe construction

13 : THE SHOE LAST

Shoe last shapes

How lasts are made

Metal, plastic, and wood lasts

14 : FOOTWEAR COSTING

Where does the money go?

Reading a factory cost sheet

Shoe part costs

15 : LOGO DESIGN FOR SHOES

What is the right logo for your shoe?

Shoe logo constructions

16 :LEATHER FOR SHOES

Leather basics

Common leather for shoes

17 : TEXTILES FOR SHOES

Fabric weaves vs. fabric knits

Backing and surface treatments

18 : SYNTHETICS FOR SHOES

Synthetic material types

Synthetic applications on shoes

19 : FOAM FOR SHOES

Foam types

Open cell vs. closed cell foam

20 : KNOW YOUR FOOTBEDS

Footbed parts

Material types for shoes

21 : FOOTWEAR MATERIAL SUPPLIERS

Working with material suppliers

List of top shoe material suppliers

22 : SHOE DESIGNERS TOOLS

The Pantone™ color system

Common tools of the shoe trades

23 : JOBS IN THE SHOE TRADE

Getting started in the shoe trades

There is a job for you

24 : QUALITY CONTROL

How to grade shoe quality?

Standard shoe inspection procedure

25 : LIFE AT A SHOE FACTORY

Look inside a real factory

Common shoe factory working conditions

26 : SHOE MAKING DICTIONARY

Shoe making terms you should know

Shoe parts diagram

Series: How Shoes are Made (Book 1)

Paperback: 220 pages

Publisher: Wade’s Place; 3rd edition (April 5, 2018)

Language: English

ISBN-10: 1519389574

ISBN-13: 978-1519389572

Product Dimensions: 8.5 x 0.5 x 11 inches

Jean (verified owner) –

J’enseigne la cordonnerie et je suis chausseur depuis 30 ans. Vos livres restent une véritable source de découverte et d’efficacité!

Jean-Luc

(I teach shoemaking and have been a shoemaker for 30 years. Your books remain a real source of discovery and efficiency!)

Stephanie –

This was a gift to a family member that has an interest in sneakers. Very well written and understandable.

Vaibhav –

Excellent resource to learn about the shoe industry.

This book provides an excellent overview of the shoe industry starting from design phase to materials selection to commercial production/commercial supply chain. The information in all chapters is presented in a easy-to-read format with plenty of pictures of the actual factories and manufacturing/testing equipment, tooling, intermediate and final product etc. The book focuses more on real-world operations of the shoe industry and less on theoretical/ academic aspects of design, materials and manufacturing. For e.g. there is a chapter on shoe assembly line which discuss different types of shoe constructions commonly used in the industry by heavy use of pictures of the shoe construction process and actual pictures of assembly lines from the factories in Asia where majority of shoes are made. There are also contacts of different suppliers of materials (e.g. foam, leather etc.) used in shoe making. The contents are particularly helpful to people who are new to shoe industry and are interested to learn about the day-to-day functioning of this industry.

The author demonstrates strong knowledge and experience of the shoe business. Details of shoe design development process, selection of different materials used in making shoes, and different processes followed by suppliers/ manufacturers are described in right amount of details. I also have to note that I corresponded with the author- Wade M regarding a few questions after reading his books. Author was prompt to respond and eager to help with my questions. During my correspondence, I greatly appreciated not only his technical expertise but also his humility and willingness to help!

I also purchased the other two books by the same author – “How to Start Your Own Shoe Company” and “Shoe Material Design Guide” and must say they complement each other well. I’d highly recommend all three books for someone who is pursuing entrepreneurial opportunities in the shoe industry and wishes to know the inner workings of this footwear development, manufacturing and global supply chain process.

Overall, I found this book to be a great read; I’d highly recommend it.

G.C. –

Awesome book! Best book if you are starting. Great information to begin making your shoes. Definitely worth the money. ! Ty. Gl

Silvertip –

Takes the mystery out of the shoe industry.

As an owner of a small US made shoe company, I have been frustrated at the last of educational materials on how shoes are made. We have unique products and have developed a lot of our own methods, which is fine, but there are times when we needed to know how certain things are done. This book helped us bridge that gap and also gave us some great leads on suppliers and others in the industry. If you’re just looking to try to make your own pair of shoes once, then there are other resources better suited for you. However, if you’re interested in seriously entering the shoe design/manufacturing market then this is a great starting place.

MR AO OSOKOYA –

Part of a Great Series of Books.

I have purchased all 3 of these books and they are a wealth of insight and information. Furthermore, I have been able to email Wade and received helpful responses from him. Really recommended.

M.A. –

I found troves of useful information. I bought all 3 books from this series.

Very informative. I am working on developing my own shoe line. I found troves of useful information. I bought all 3 books from this author!

Matthew H. –

If you are interested in designing shoes, read this book. If you want to start and own a shoe company, read this book. If you already have a brand and are interested in adding shoes to your lineup, read this book. Plainly said, this book will save you time and frustration assessing the footwear industry and if it’s something for you. If you’re thinking of participating in the shoe game in any way, the contents of this book will add significant value to your vision, plans, business, etc. How Shoes are Made is a goldmine of useful information that you can immediately integrate into your footwear dreams, I highly recommend it.

Rene C –

Great book for the non-sneaker industry veteran.

While people working within the shoe industry may be able to pick at various aspects of the book (I see other reviewers having done this), to someone without an industry background, this book is full of helpful information on the contemporary sneaker production process – information that isn’t easy to acquire in one consolidated place otherwise. I greatly appreciate all the knowledge shared in this book and would highly recommend it to anyone (like myself) that is looking for some foundational insight into the many facets of sneaker production.

D. West –

I love this book!!

I bought it as a coffee table book for our home because my husband is a novice designer and loves this stuff but came to find out that it has something for everyone to learn from. It is so interesting to delve into a world you know nothing about and learn so much!! Mr Motawi is a great author and i hope he writes other informational books!! thank you!